Reliable Air Compressor Rubber Parts Manufacturer For Industrial OEM

Y&F air compressor rubber parts are engineered for durability, precision, and long-term sealing performance in demanding industrial settings. These components are critical in maintaining efficiency, reducing vibration, and extending the lifespan of air compressors.

Key Features:

-

Excellent Sealing Performance: Prevents air leakage and improves compressor efficiency.

-

Vibration Damping: Protects equipment and reduces noise.

-

Premium Rubber Materials: NBR, EPDM, silicone for oil, heat, and weather resistance.

-

Custom Fit & OEM Support: Tailored designs to match different compressor models.

-

Industrial-Grade Durability: Built to withstand high pressure and continuous operation.

-

Global B2B Service: Fast delivery, multilingual support, and quality assurance for international buyers.

Air Compressor Rubber Parts Series

Y&F offers a wide range of air compressor rubber parts including grommets, mounts, gaskets, seals, and hoses. Each product is designed to deliver optimal performance in sealing and vibration control. With material and dimension customization available, we ensure compatibility with global compressor models. Our series supports OEM manufacturing, aftermarket replacement, and distributor supply needs.

Tailor-Made For Compressor Compatibility

Every part is manufactured to match compressor specs, ensuring perfect fitment, better sealing, and reduced wear—ideal for industrial OEM and global distribution.

Why Choose Y&F Air Compressor Rubber Parts To Power Your Equipment

Y&F delivers precision-engineered rubber parts for air compressors, ensuring leak-proof sealing and vibration absorption across various industries. Our solutions reduce downtime, support OEM manufacturing, and improve system efficiency. With fast delivery and global service, we are a trusted partner for buyers seeking quality and reliability.

Air Compressor Rubber Parts Applications

Air compressor rubber parts are widely used in manufacturing, construction, HVAC, and automotive sectors to ensure airtight systems and stable performance.

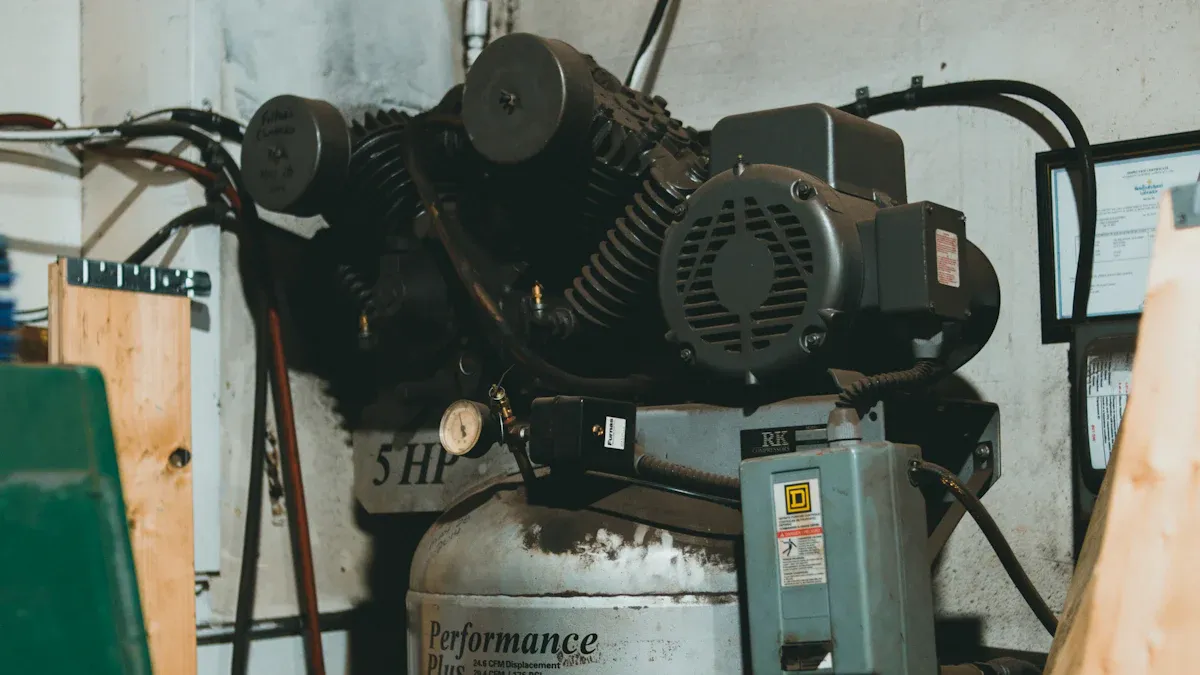

Industrial Compressors

Used in factory air systems for sealing, noise reduction, and energy efficiency.

Construction Equipment

Applied in portable compressors on-site to resist shock and maintain airtight operation.

Automotive Service

Ensures performance of garage air tools and compressors in high-demand settings.

HVAC Systems

Enhances efficiency and stability in heating, ventilation, and air conditioning systems.

Air Compressor Rubber Components Guide: Specs, Materials, Delivery, and Custom Services

Y&F specializes in rubber parts manufacturing with strict QC, short lead times, and material certifications like RoHS and REACH. We use injection and compression molding for custom parts, offering various hardness, color, and tolerances. Our lead time is 7-15 days for standard parts and 20-30 days for tooling. Shipping by sea, air, or express with full documentation support. OEM and logo branding options available.

Download Y&F Air Compressor Rubber Parts Catalog PDF

Air Compressor Rubber Parts Manufacturer

An Air Compressor Rubber Parts Manufacturer makes rubber parts for air compressors. These parts help your air compressor work well and stay quiet. Picking the right manufacturer helps your machine work better and last longer. It also helps you save money. Studies show that good parts make machines work better and break down less. The global compressor seals market is growing quickly. This shows that more people want energy-saving solutions. Companies like Y&F have lots of experience. They use strong materials and check quality carefully. This helps them make good parts that keep your compressors working well.

Key Takeaways

- Picking the right rubber parts and manufacturer helps your air compressor work better. It also makes it last longer and saves you money.

- Rubber parts like seals, gaskets, O-rings, and bushings all have important jobs. They help compressors run smoothly and quietly.

- Good manufacturers use strong materials and careful molding methods. This makes parts that last long, fit well, and do not wear out fast.

- Find suppliers with quality certificates, quick delivery, and good customer support. This helps you get safe and reliable parts.

- Specialist manufacturers give expert advice, custom choices, and tested parts. These things lower repairs and help your compressor work better.

Rubber Parts Overview

Key Components

Air compressor rubber parts have many important pieces. Each one helps your air compressor work well. Here are some main types you might find:

- Seals: These stop air and fluids from leaking.

- Gaskets: These make tight seals between different parts.

- O-rings: These stop leaks at joints and connections.

- Hoses: These move air or fluids to other parts.

- Bushings: These help lower friction and wear.

It is also important to know about the materials used. Manufacturers pick natural rubber, NBR, EPDM, silicone, or neoprene. Each material has its own strengths. Some resist oil, heat, or weather better than others.

How these parts are made is important, too. Common ways include compression molding, injection molding, extrusion, blending, and laminating. These methods help make parts that fit your compressor just right.

Tip: Always look at the material and how it is made when picking rubber parts. This helps you get the best use and longest life.

| Component Property | Description | Role in Performance |

|---|---|---|

| Tensile Strength | Maximum stress before breaking | Resists stretching and tearing |

| Elongation | Stretch percentage before breaking | Shows flexibility and ability to conform |

| Hardness (Shore A) | Resistance to indentation | Affects durability and wear resistance |

| Compression Set | Permanent deformation after compression | Impacts shape retention and function |

| Temperature Resistance | Range without degrading | Ensures use in extreme conditions |

Functions

Every rubber part in your air compressor has a job. These jobs help your compressor work better and last longer.

| Rubber Part Component | Function |

|---|---|

| Rubber Feet | Lower vibration and noise, protect surfaces, absorb shocks |

| Isolator Pads | Give stability, resist corrosion, lower noise and vibration |

| Seals and Gaskets | Stop leaks, keep dust and water out, keep things airtight |

| O-rings | Block leaks at joints, help the compressor work better |

| Bushings | Lower friction, help moving parts last longer |

Rubber seals and gaskets stop leaks of air and fluids. They also keep dust and water away from key parts. Rubber feet and isolator pads make less noise and vibration. This protects your compressor and makes it quieter. Bushings help moving parts last longer by lowering friction.

Using the right rubber parts helps your air compressor run well, save energy, and avoid expensive repairs.

Air Compressor Rubber Parts Manufacturer

Manufacturing Process

When you pick an Air Compressor Rubber Parts Manufacturer, you want to know how they make parts. Y&F uses special molding methods to make strong rubber parts. These include compression molding, transfer molding, and injection molding. Each way helps make parts that fit your compressor and last a long time.

- Rubber injection molding makes exact parts fast and with less waste. This way, you get the same good quality every time.

- Compression molding is good for bigger parts. It keeps the parts the same and helps your machines last.

- Transfer molding shapes tricky parts with great care. This lowers mistakes and makes the parts stronger.

- Vulcanization is a curing step that makes rubber up to 40% tougher. It helps rubber stretch and work in hard places.

- After making the parts, tests check for stress and aging. These tests find problems like bubbles or rough spots before you get the parts.

Here is a table that shows some main molding ways and what they do:

| Molding Process | Description & Innovations |

|---|---|

| Compression Molding | Uses heat and pressure for simple, cost-effective parts. Good for low to medium volume. Keeps shapes precise. |

| Transfer Molding | Moves rubber into molds quickly. Makes complex parts and bonds rubber to metal. Good for higher volumes. |

| Injection Molding | High precision and repeatability. Great for tight-tolerance parts like O-rings. Fast for large orders. |

| Rubber-to-Metal Molding | Bonds rubber to metal for vibration control. Adds strength and chemical resistance. |

Y&F uses these ways to make sure every part works well for you. You get parts that last and help your air compressors run better.

Quality Standards

A trusted Air Compressor Rubber Parts Manufacturer follows strict rules for quality. Y&F checks each part to meet world rules like RoHS and REACH. These rules keep bad chemicals out of rubber parts. They help keep you and the earth safe. Companies test rubber in labs to make sure there is no lead or mercury. This helps you feel safe and makes it easier to follow your own safety rules.

Y&F also keeps up with new rules. They update their papers and tell you about changes. This helps you follow the newest laws and keeps your business safe. Certificates like ISO 9001 and ISO 14001 show that Y&F cares about quality and safety. These papers help you trust them and know you get good parts.

- Certificates like ISO, CE, and REACH show products are safe and made by strict rules.

- These marks help you trust the maker and sell in many countries.

- Checks and updates keep quality high and protect your good name.

Product Range

A good Air Compressor Rubber Parts Manufacturer gives you many products. Y&F offers lots of choices, like seals, gaskets, O-rings, hoses, rubber mounts, and flexible couplings. They use top materials like NBR, EPDM, and silicone. These help the parts last and work in tough places.

- NBR fights oil and fuel, so it is great for seals and hoses in hard jobs.

- EPDM stands up to weather, ozone, and aging. It works well outside and lasts a long time.

- Silicone can take very hot or cold places and stays bendy. It is good for parts that face heat or cold.

Y&F lets you pick parts that fit your needs. You can choose how hard, what color, and what size you want. They help with OEM, replacement parts, and big business orders. You get fast shipping, even for custom parts. Normal parts ship in 7-15 days, and custom tools take 20-30 days.

Tip: If you pick a maker like Y&F, you get parts that fit, last, and help your business do well.

Choosing a Manufacturer

Evaluation Steps

When you pick an Air Compressor Rubber Parts Manufacturer, you need a simple plan. First, check how each company makes and tests its products. You can compare suppliers like Y&F, Alibaba, Atlas Copco, and Vikrant International step by step.

Here is a table that lists common steps and what they mean:

| Evaluation Step / Benchmark | Description | Purpose |

|---|---|---|

| CAGI Performance Verification | Outside experts check product performance data. | Makes sure claims are true and reliable. |

| Isentropic Efficiency Metric | Measures how well compressors work at set pressure. | Helps you find the most efficient parts. |

| ISO 50001 Energy Management Audits | Looks at energy use and system performance. | Helps lower costs and save energy. |

| ISO 8573-7 Microbial Testing | Tests for germs in compressed air. | Makes sure air is safe to use. |

| NFPA 99 Medical Air Quality | Checks air and gas safety for medical use. | Makes sure air is safe for hospitals. |

You should also check supplier quality numbers. These include delivery time, order cycle time, and perfect order rate. For example, Y&F ships standard parts in 7-15 days and custom tools in 20-30 days. If a company delivers on time and has few defects, you know they are reliable.

Tip: Use a checklist or scorecard to compare suppliers. This helps you make a fair and easy choice.

Key Qualities

The best manufacturers focus on speed, quality, and helping customers. You want a partner who ships fast, keeps costs low, and helps you after you buy. Y&F stands out with quick lead times, service in many languages, and full paperwork and logo branding. These things help you work in different places and keep your brand strong.

Here are some important qualities to look for:

- Fast Delivery: Short wait times help you avoid delays and finish projects.

- Consistent Quality: Fewer problems mean you get good parts every time.

- Strong Support: Service in many languages and clear papers help you solve problems and follow rules.

- Branding Options: Custom logos help you build your brand and stand out.

- Advanced Technology: Digital tools and real-time updates make things faster and better.

- After-Sales Service: Good help after buying keeps your machines working longer.

Companies like Y&F use digital systems to track orders and quality. This means you get updates quickly and can trust the info you get. Comparing these things with other suppliers like Alibaba, Atlas Copco, and Vikrant International helps you see what each company offers.

Questions to Ask

Before you pick a supplier, ask questions to learn about their strengths and weaknesses. Here are some good questions:

- How fast can you ship standard and custom parts?

- What quality checks do you use for your rubber parts?

- Can you give papers in different languages?

- Do you offer logo branding or special packaging?

- What is your defect rate and how do you handle returns?

- How do you help customers after they buy?

- Can you share customer feedback or references?

- What certifications do your products have?

Note: Asking these questions helps you find a manufacturer who fits your needs and supports your business as it grows.

When you compare Y&F with others, look at their answers to these questions. Check their shipping times, service, and how they help your brand in other countries. This way, you can pick the best Air Compressor Rubber Parts Manufacturer for your business.

Benefits of Specialists

Longevity

If you pick a specialist for air compressor rubber parts, your equipment lasts longer. Specialists know a lot and use their skills to make sure each part is high quality. Companies like Rahco Rubber show that careful workers make better parts that last longer. These experts choose the best rubber, like EPDM or silicone, which can handle heat, chemicals, and wear. This helps seals, gaskets, and hoses work hard without breaking. Specialists also store rubber the right way so it does not get old too fast. By using good materials and smart methods, they help your compressors work well for many years.

Specialists also make parts for tough places. For example, Goodyear Rubber makes custom seals and dampeners that can take lots of pressure and shaking. This extra care helps your machines last longer and break down less.

Cost Savings

Working with a specialist saves you money over time. Good rubber parts last longer, so you do not need new ones often. This means you spend less on repairs and your machines stop less. Specialists also make parts that fit your needs. When parts fit right, your compressor works better and uses less energy.

Using the right parts from a specialist helps you avoid big repair bills and keeps your business running well.

Specialists test every part to make sure it is good. This careful testing means fewer broken parts and less waste, which saves you money later.

Technical Support

Specialists give strong technical support to help you fix problems fast. You get advice from experts who know what you need. They help you pick the best rubber and design for your compressor. Many specialists use special tools to test their products. They also help you after you buy, so you always have support.

- You can get:

- Custom parts for your needs

- Quick answers to questions

- Help with putting in and taking care of parts

- Detailed product information

This kind of support helps your compressors work well and last longer. You can trust specialists to help you at every step.

Picking the right Air Compressor Rubber Parts Manufacturer keeps your machines working well. It also helps you save money as time goes on. Good suppliers check their parts with strong tests. They have important certificates that make things safer. This helps your business look better and lowers problems. Expert makers design parts that help machines stay steady. These parts break less and help your business get bigger. Use the tips in this guide to compare different suppliers. This will help you make smart choices for your air compressors.

FAQ

What rubber materials work best for air compressor parts?

You should look for NBR, EPDM, or silicone. NBR resists oil. EPDM stands up to weather. Silicone handles heat and cold. Each material helps your compressor work better in different conditions.

How do I know if a rubber part fits my compressor?

Check your compressor’s model number. Ask the manufacturer for a compatibility chart. You can also measure the old part and compare it to the new one. Y&F offers custom sizing for a perfect fit.

Why do rubber parts matter for air compressors?

Rubber parts stop leaks, lower noise, and cut down on vibration. Good parts help your compressor last longer and work more efficiently. You save money on repairs and energy.

Can I get custom rubber parts with my company logo?

Yes, you can. Many manufacturers, like Y&F, offer logo branding and special packaging. This helps you build your brand and makes your parts easy to identify.

How fast can I get replacement rubber parts?

Standard parts usually ship in 7-15 days. Custom orders may take 20-30 days. You should ask your supplier for exact delivery times before you order.